High-Efficiency Die Preheating Burners for Die Casting & Forging

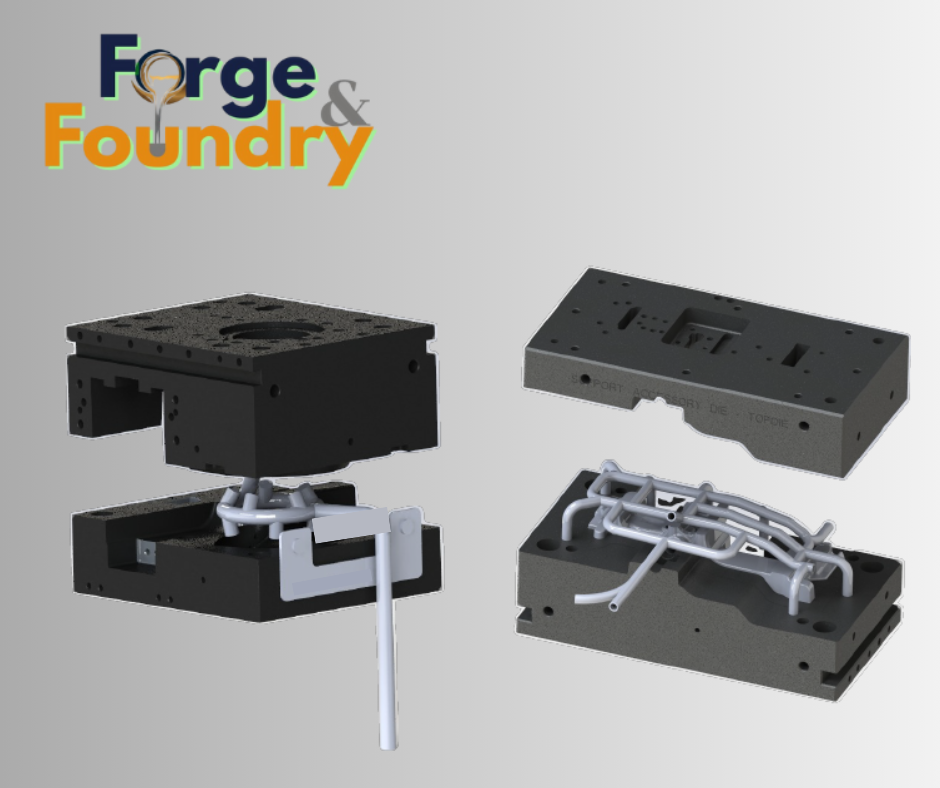

Maximize the lifespan and quality of your tooling with our industrial-grade Die Preheating Burners. Engineered for high-temperature environments in die casting and forging operations, our robust gas burners deliver rapid, precise, and **uniform die temperature** across complex mould surfaces.

Proper die preheating is essential to prevent costly defects like casting cracks, cold shuts, and premature tool wear caused by thermal shock. Our advanced combustion systems feature fuel-efficient technology and fine control settings, ensuring optimal heat transfer while significantly reducing energy consumption and operational costs.

Whether you require a system for initial preheating or to maintain consistent temperature during production breaks, our die preheating burners ensure superior metal flow, enhance dimensional accuracy, and contribute directly to extended die lifeand reduced scrap rates. Explore our versatile range of solutions designed for seamless integration into your foundry or forging line.