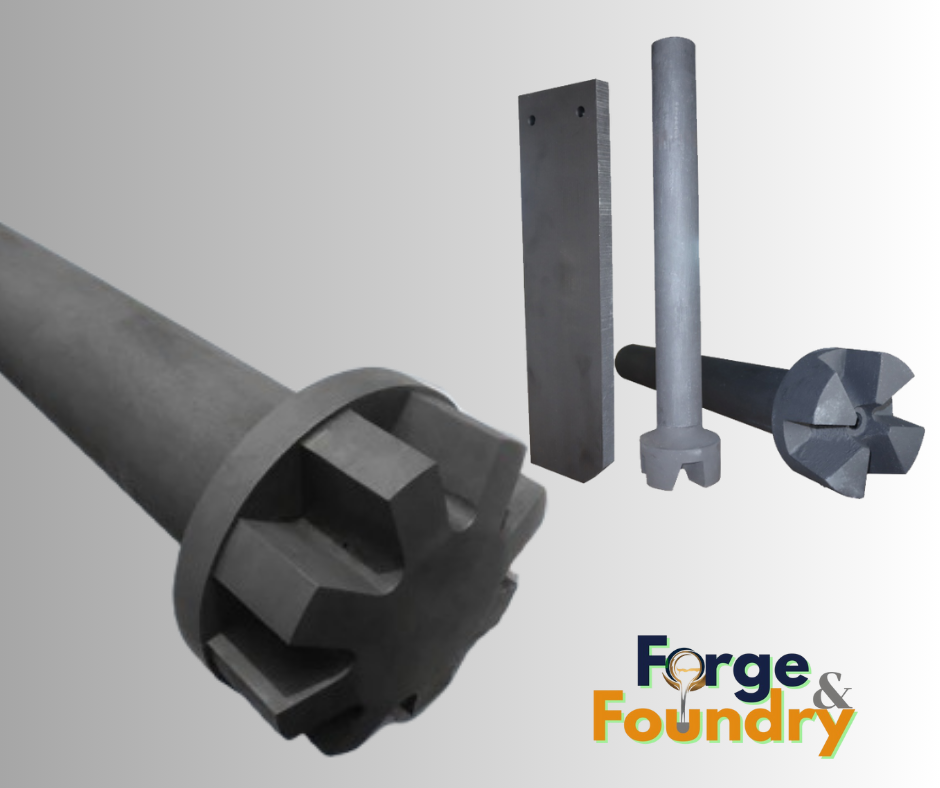

Degassing machine rotors and shafts are critical components in the molten metal treatment process, particularly in foundries handling non-ferrous metals like aluminum. Their primary function is to efficiently remove dissolved hydrogen gas and non-metallic inclusions, which can lead to significant defects such as porosity in the final casting. The rotor, typically positioned at the end of the shaft, spins at high speeds within the molten metal, creating a vortex and dispersing an inert purging gas (like argon or nitrogen) into fine, uniformly distributed bubbles. This maximizes the contact surface area between the gas bubbles and the molten metal, facilitating the effective flotation and removal of impurities and dissolved gases, ultimately leading to a cleaner, higher-quality melt.

The design and material selection for these components are paramount to their performance and longevity in the harsh, high-temperature environment of molten metal. Rotors and shafts are often manufactured from advanced materials such as high-purity graphite or specialized ceramics, which offer exceptional resistance to thermal shock, oxidation, and erosion. Their robust construction ensures consistent and reliable operation, minimizing the need for frequent replacements and reducing costly downtime in production. By contributing to superior metal purity and extending the lifespan of critical equipment, high-quality degassing machine rotors and shafts are indispensable for achieving efficient, cost-effective, and high-quality casting operations.

| Advantage/Benefit | Description |

|---|---|

| Improved Metal Purity & Quality | Efficiently removes dissolved hydrogen gas and non-metallic inclusions from molten metal, leading to fewer defects (e.g., porosity) and higher-quality castings. |

| Enhanced Degassing Efficiency | The precision design of the rotor creates fine, uniformly distributed inert gas bubbles, maximizing the contact area with the molten metal for optimal hydrogen removal. |

| Extended Lifespan & Durability | Manufactured from advanced, high-purity graphite or ceramic materials, these components offer exceptional resistance to thermal shock, oxidation, and erosion by molten metal. |

| Reduced Maintenance & Downtime | The long service life of high-quality rotors and shafts minimizes the frequency of replacements, leading to significant reductions in maintenance time and production interruptions. |

| Cost Savings | By improving casting quality (fewer rejects) and extending component life, these parts contribute to lower operational costs and better overall profitability. |

| Consistent Performance | Reliable rotors and shafts ensure repeatable and stable degassing performance, leading to consistent metal quality across batches. |

| Energy Efficiency | Optimal design promotes efficient gas utilization, potentially reducing the consumption of inert gases and overall energy usage in the degassing process. |